IRON FOUNDRY BASICS

What is ironfounding?

lronfounding is fundamental to modern industry, yet it can be equally well operated on a small

scale by small numbers of people in rural areas.

Iron shapes or "castings" are made by pouring molten metal into moulds made of sand. Small parts

which cannot easily be shaped by the method of forging are cheaply and simply produced in this

way.

Cast iron is a brittle material which is strong when compressed, but relatively weak when pulled or

bent. These qualities determine the uses of cast iron, which are very numerous.

Cast iron is found in motor cars, tractors, ships, factories (sic), mines, houses, in the streets and

roads, and almost any place one cares to look. For example, the cylinder head, water pump and

exhaust manifold of a car; the grid, manhole cover and lamp post in the street; parts of a

compressor, many parts of agricultural, building and textile equipment - all are made of cast iron.

Every day of our lives, something made of this material is used by most people.

A decision on the level of technology - or the size and type of foundry to be set up - must depend

on such factors as the capital available, raw materials supply and labour availability, the

characteristics of the market and the size and type of castings required.

When one has chosen the size and type of furnace, one must also make sure that there are enough

moulds to take the quantity of metal melted, and that there is always enough metal to complete a

pour once it is started.

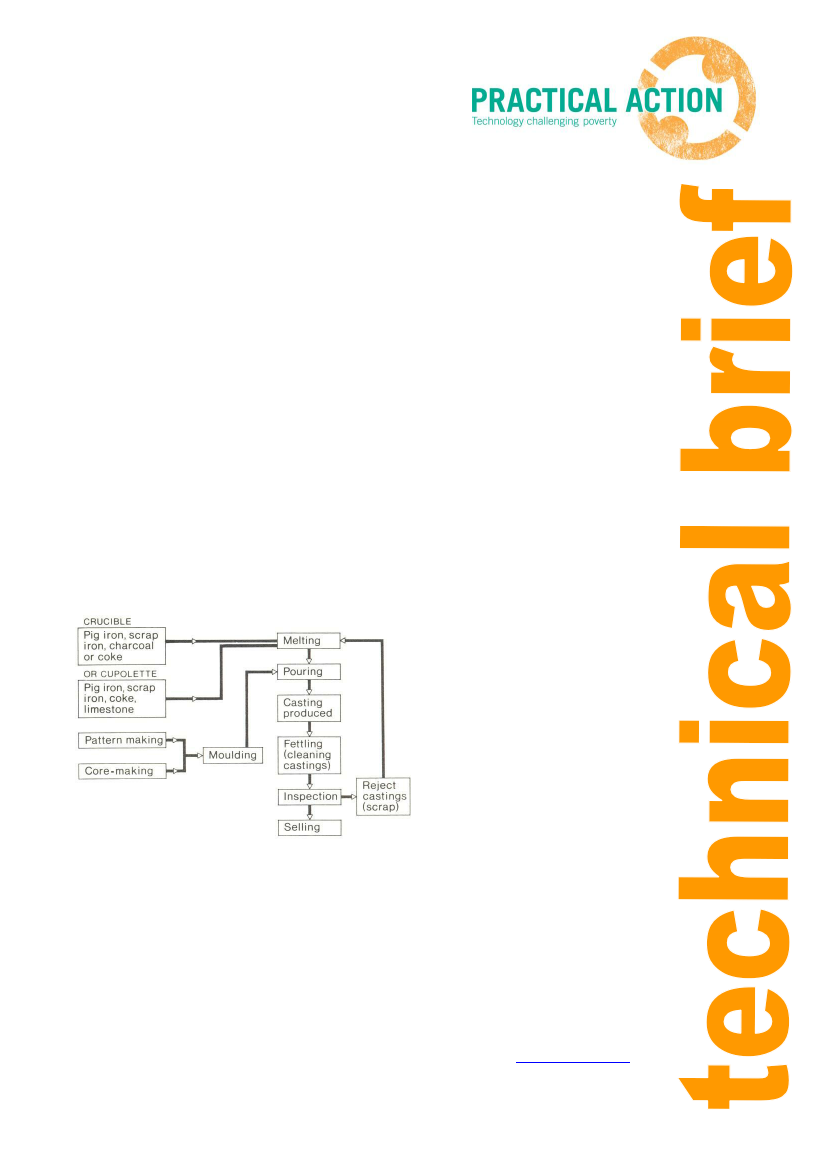

Sequence of operations

For ironfounding there are three main

levels of technology:

(1) Simple operations needing low

capital and low power resources,

utilizing the crucible furnace.

(2) More elaborate operations for

longer runs, requiring more expertise

and labour, capital and power, and

using the small cupolette type of

furnace.

(3) Elaborate operations requiring

high capital investment, high power

resources, and expensive melting

equipment.

The present pamphlet covers the first two of these three possibilities. Information on the

mechanised foundry can be easily obtained from any large foundry equipment manufacturer.

Practical Action, The Schumacher Centre, Bourton on Dunsmore, Rugby, Warwickshire, CV23 9QZ, UK

T +44 (0)1926 634400 | F +44 (0)1926 634401 | E infoserv@practicalaction.org.uk | W www.practicalaction.org

______________________________________________________________________________________________

Practical Action is a registered charity and company limited by guarantee.

Company Reg. No. 871954, England | Reg. Charity No.247257 | VAT No. 880 9924 76 |

Patron HRH The Prince of Wales, KG, KT, GCB